Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

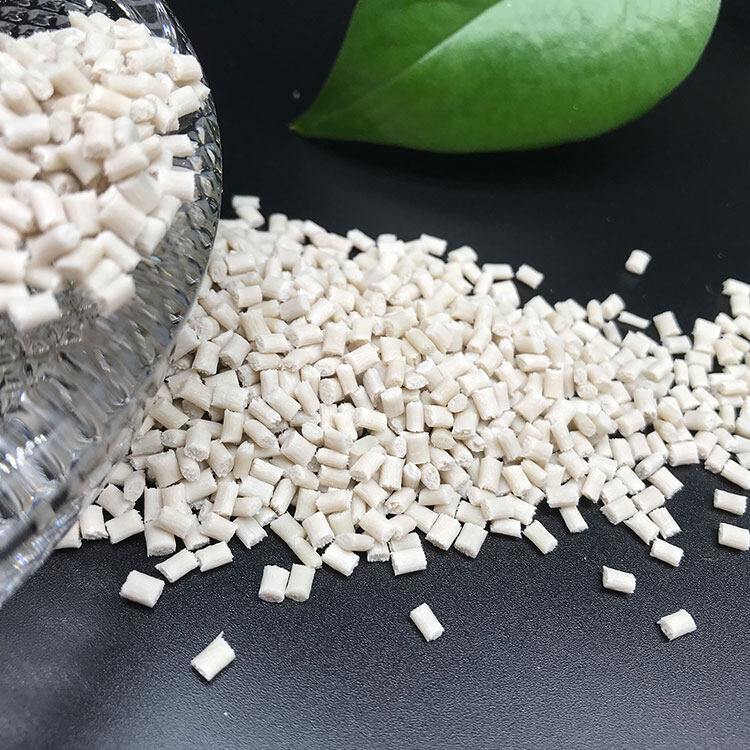

PA6 GF30 E070830YL

Glass Filled: 30%

UL94 1.6mm V0

Halogen added

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of PA6 GF30 E070830YL PA6 Granules

(PA6 V0 Nylon 6 Granule Nylon 6 Chips PA6 Gf 30% Granule)

| 拓扑新材料 名称: PA6 TOPONEW- 牌号: E070830YL |

||||

| 产品简介 Product Description | 主要应用 Applications | |||

| ·30%玻纤增强尼龙6 30% glass fiber reinforced PA6 | ·注塑成型 Injection molding | |||

| ·优异的耐耐热性能 Excellent heat stability | ·良好的机械性能 Good mechanical properties balance | |||

| 性能 Properties |

测试标准 Test Method |

测试条件 Test Condition |

单位 Unit | 典型值 Typical Values |

| 物理性能 Physical properties | ||||

| 密度 Specific Gravity | ISO 1183 | 23℃ | g/cm | 1.6 |

| 熔融指数 | ISO 1183 | 235℃,2.16kg | g/10ming | 18 |

| 灰份Ash | ISO 3451 | 800℃,30min | % | 30 |

| 机械性能 Mechanical properties | ||||

| 拉伸强度Tensile Strength | ISO 527 | 50mm/min | MPa | 140 |

| 弯曲强度 Flexural Strength | ISO 178 | MPa | 210 | |

| 弯曲模量 Flexural Modulus | ISO 178 | 2mm/min | MPa | 9800 |

| 简支梁缺口冲击强度 Charpy Notched Impact Strength |

ISO 180 | 23℃ | kJ/㎡ | 15 |

| 热性能 Thermal properties | ||||

| 热变形温度 Heat deflection temperature |

ISO 75 | 1.80MPa | ℃ | 190 |

| 其它性能 Othe properties | ||||

| 灼热丝耐燃性能Ignition resistance of burning wire/GWFI | IEC 60695-2-12 | GWFI: 960/3.0 | PASS | |

| 相对漏电起痕指数(CTI) | IEC 60112 | V | 400 | |

| 阻燃性 Flammability | UL 94 | - | 1.6mm | VO |

PA6 GF30

PA 6 GF 30 refers to PA6 plastic granules reinforced with 30% glass fibers. Nylon 6 30 gf density is around: 1.6 g/cm^3. This modification enhances the strength, stiffness, and thermal properties of the PA6 resin, making it suitable for applications that require high mechanical performance.

PA6 GF30 Halogen Added Granules are a type of engineering plastic composite that consists of Polyamide 6 (PA6) as the base material and 30% glass fiber reinforcement. These granules are specifically formulated to provide enhanced mechanical properties, such as increased strength, stiffness, and heat resistance compared to regular PA6.

The term "halogen-added" indicates that these granules contain halogens, which are chemical elements such as chlorine, fluorine, bromine, and iodine. Halogens are commonly used as flame retardants in various plastics to improve their fire resistance properties. The presence of halogens in these granules allows them to meet specific fire safety regulations by reducing the flammability and spread of flames.

PA6 GF30 Halogen Added Granules are often utilized in applications where high strength, rigidity, and flame resistance are required. They are commonly used in automotive components, electrical connectors, industrial equipment, and consumer goods. The glass fiber reinforcement provides excellent dimensional stability, while the addition of halogens enhances the flame retardant properties of the material.

Overall, PA6 GF30 Halogen Added Granules offer a favorable combination of mechanical properties and flame resistance, making them suitable for various industries that require both structural integrity and fire safety measures.

At TOPONEW, we specialize in providing top-quality plastic granules, including PA6 plastic granules. Our granules are manufactured with precision and are designed to meet specific industry standards and customer requirements. With our range of PA6 plastic granules, you can achieve optimal performance in your manufacturing processes.

Trust TOPONEW as your reliable partner for all your plastic granule needs. We're dedicated to delivering superior products that meet your expectations. Let us assist you in discovering the endless possibilities of PA6 plastic granules!

FAQ

1. What is PA6 10

PA6 10, also known as nylon 6 10, is a type of nylon that incorporates a different monomer in its polymer structure compared to traditional nylon 6. The "6 10" in the name refers to the number of carbon atoms in the monomers used to produce the polymer.

2.Nylon 6 vs Nylon 66

When comparing nylon 6 (PA6) and nylon 66 there are a few key differences to note. Nylon 66 is another commonly used nylon variant that offers enhanced heat resistance and dimensional stability compared to nylon 6. On the other hand, nylon 6 is often preferred for its superior impact resistance and flexibility.

3.Is nylon 6 a polyamide?

Yes, nylon 6 is a type of polyamide. Polyamides are a class of polymers that contain amide (-CO-NH-) linkages along the polymer chain. Nylon 6 is specifically known as polyamide 6, as it is made up of repeating units of the monomer called caprolactam.

Polyamides, including nylon 6, are widely used in various industries due to their excellent mechanical properties, such as high strength, toughness, and durability. They also possess good resistance to wear, heat, and chemicals, making them suitable for applications ranging from textiles and engineering plastics to automotive parts and electrical components.

PA6 GF30 refers to Polyamide 6 (Nylon 6) material that is reinforced with 30% Glass Fiber (GF). This composite material combines the benefits of Polyamide 6 with the added strength and stiffness provided by the glass fibers.

Here are some key characteristics of PA6 GF30:

-

Improved Strength: The addition of 30% glass fibers enhances the tensile and flexural strength of the material, making it suitable for applications requiring high mechanical performance.

-

Stiffness: Glass fibers contribute to increased stiffness and rigidity of the Polyamide 6 matrix, providing dimensional stability and resistance to deformation under load.

-

Heat Resistance: PA6 GF30 generally exhibits good heat resistance compared to unreinforced Polyamide 6, making it suitable for applications where elevated temperatures are present.

-

Enhanced Wear Resistance: The presence of glass fibers can improve the wear resistance and durability of PA6 GF30, extending the lifespan of components made from this material.

PA6 GF30 is commonly utilized in various industries such as automotive, aerospace, electronics, and consumer goods where a balance of strength, stiffness, and heat resistance is required in the final product. As always, it is important to consult the technical datasheets provided by the material supplier for specific properties and guidelines on processing PA6 GF30.

Download

-

PA6GF30-E070830YL.pdf

Download PA6GF30-E070830YL.pdf